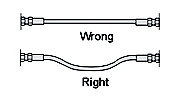

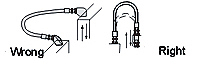

Since hose may change in length from +2% to -4%.

Under the surge of high pressure,provide sufficient Slack for expansion and contraction

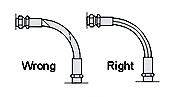

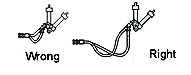

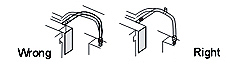

Hose should not be twisted.

Hose is weakededwheninstalledinbwistedposition.

Also Pressure in twisted hose tends to loosen fitting Connections

Design So that machine motion produces bending rather that bwisting

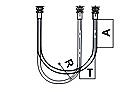

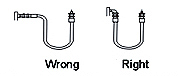

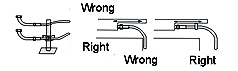

Never use a bending radius less than minimum shownin the hose specilcationthe bending radius of hose should be far away from the hose fitting (A>1.5R).

Leave proper Length when the hose is connected

Hose bending radius is bigger when it is in motion

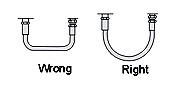

Choise proper fittings,avoid too small bending radius and excess force

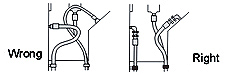

Choice proper fittings,avoid twisting in hose lines bent in two planes

Choice proper fittings,avoid excessive hose length

Avoid twisting in hose by using clamp properly

Reduce friction,avoid hose touching the object directly or far Bway from the object